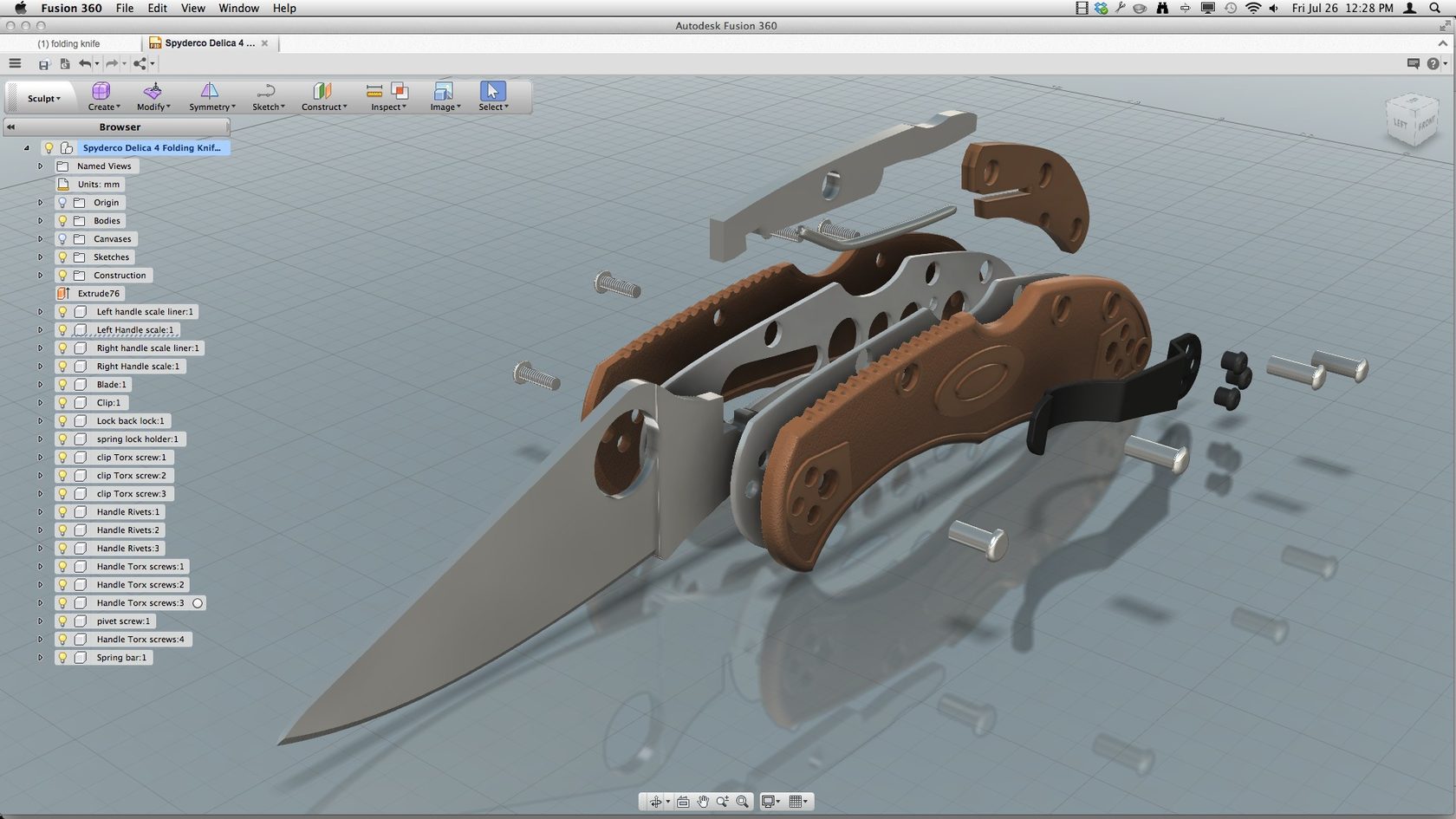

Watertight: A printable model must not have any holes in its surface.You simply cannot print an object that has a ‘paper-thin’ wall without substance. Therefore, when turning a 3D model into a real 3D print, the wall thickness or volume information of the model is needed. Wall Thickness: Printers need information about how thick you intend the wall of your object to be (or if you want to print a completely solid model).Chances are you already respect them in Fusion 360 without even knowing that they exist. That’s why the transition from virtual 3D model to actual 3D print is quite easy with this software. Luckily for us, Fusion 360 is mainly used by industrial designers to create functional parts. This is a problem in particular for programs mostly used by visual artists and game developers. A 3D model might look perfect on your screen, but would not be able to exist as a geometrical object in the real world. So let’s get started!Īs with any other program, Fusion 360 users need to make sure to stick to certain design rules when it comes to 3D printing. We will learn how to model, edit, prepare and 3D print a Fusion 360 design.

It combines powerful functionalities with a beginner-friendly interface and a relatively easy learning curve. In this tutorial, we will dive deeper into the 3D printing capabilities of Fusion 360. Autodesk Fusion 360 is one of the most popular programs among the 3D printing community, especially for those interested in industrial design.

0 kommentar(er)

0 kommentar(er)